The Full Manufacturing Workflow of Dartboards and Darts Explained

Darts and dartboards may appear simple on the surface, but their performance, durability, and safety depend heavily on a precise and well-controlled manufacturing process. For global brands, distributors, and importers, understanding how these products are made is essential when selecting a reliable dart manufacturing factory.

- Part 1: Dart Manufacturing Process Explained in Detail

- 1. Raw Material Selection for Darts

- 2. Dart Barrel CNC Machining

- 3. Tip Manufacturing and Treatment

- 4. Shaft Production (Injection Molding or CNC)

- 5. Flight Printing and Die Cutting

- 6. Dart Assembly and Performance Testing

- Part 2: Dartboard Manufacturing Process Explained in Detail

- 1. Sisal Fiber Selection and Conditioning

- 2. Sisal Compression and Board Formation

- 3. Board Surface Assembly

- 4. Wiring System Installation

- 5. Frame and Backboard Construction

- 6. Dartboard Quality Testing

- Part 3: Customization, Packaging, and Logistics

- Conclusion

- FAQ

Part 1: Dart Manufacturing Process Explained in Detail

1. Raw Material Selection for Darts

The dart manufacturing process begins with material selection, which directly affects weight balance, durability, and throwing accuracy.

-

Dart Barrels: Typically made from tungsten alloy or brass. Tungsten allows slimmer barrels at the same weight, preferred by professional players.

-

Dart Tips: Steel tips for traditional boards; plastic soft tips for electronic dartboards.

-

Shafts: Nylon, polycarbonate, or aluminum materials selected for strength and flexibility.

-

Flights: PET or PVC sheets chosen for consistent aerodynamic behavior.

All raw materials undergo hardness, density, and composition checks before entering production.

2. Dart Barrel CNC Machining

The dart barrel is the most critical component and requires high-precision processing.

Manufacturing steps include:

-

CNC turning to achieve exact diameter and weight

-

Precision cutting to control length and balance point

-

Knurling or grip-pattern engraving for finger traction

-

Surface finishing such as polishing, sandblasting, or coating

Tolerances are tightly controlled, often within ±0.05g, to ensure consistency across mass production.

3. Tip Manufacturing and Treatment

-

Steel tips are cut, hardened, and tempered to resist bending.

-

Soft tips are injection-molded and tested for impact resistance and thread accuracy.

Tips are tested for penetration, breakage resistance, and thread compatibility with barrels.

4. Shaft Production (Injection Molding or CNC)

Shafts are produced via injection molding or CNC machining depending on material type.

Key control points:

-

Thread precision to prevent loosening

-

Straightness and flexibility balance

-

Impact resistance under repeated throws

5. Flight Printing and Die Cutting

Flights are produced through a multi-step process:

-

Graphic printing using UV or offset printing

-

Die cutting into standardized shapes

-

Folding and angle forming for aerodynamic stability

Each batch is inspected for thickness, symmetry, and print durability.

6. Dart Assembly and Performance Testing

All components are assembled into finished darts and tested for:

-

Weight accuracy

-

Center of gravity

-

Flight stability during throw simulation

Only darts that meet factory performance standards proceed to packaging.

Part 2: Dartboard Manufacturing Process Explained in Detail

1. Sisal Fiber Selection and Conditioning

Professional dartboards are made from natural sisal fibers, sourced and graded by length, strength, and moisture content.

Before processing, fibers are:

-

Cleaned and sorted

-

Conditioned for humidity balance

-

Prepared for high-pressure compression

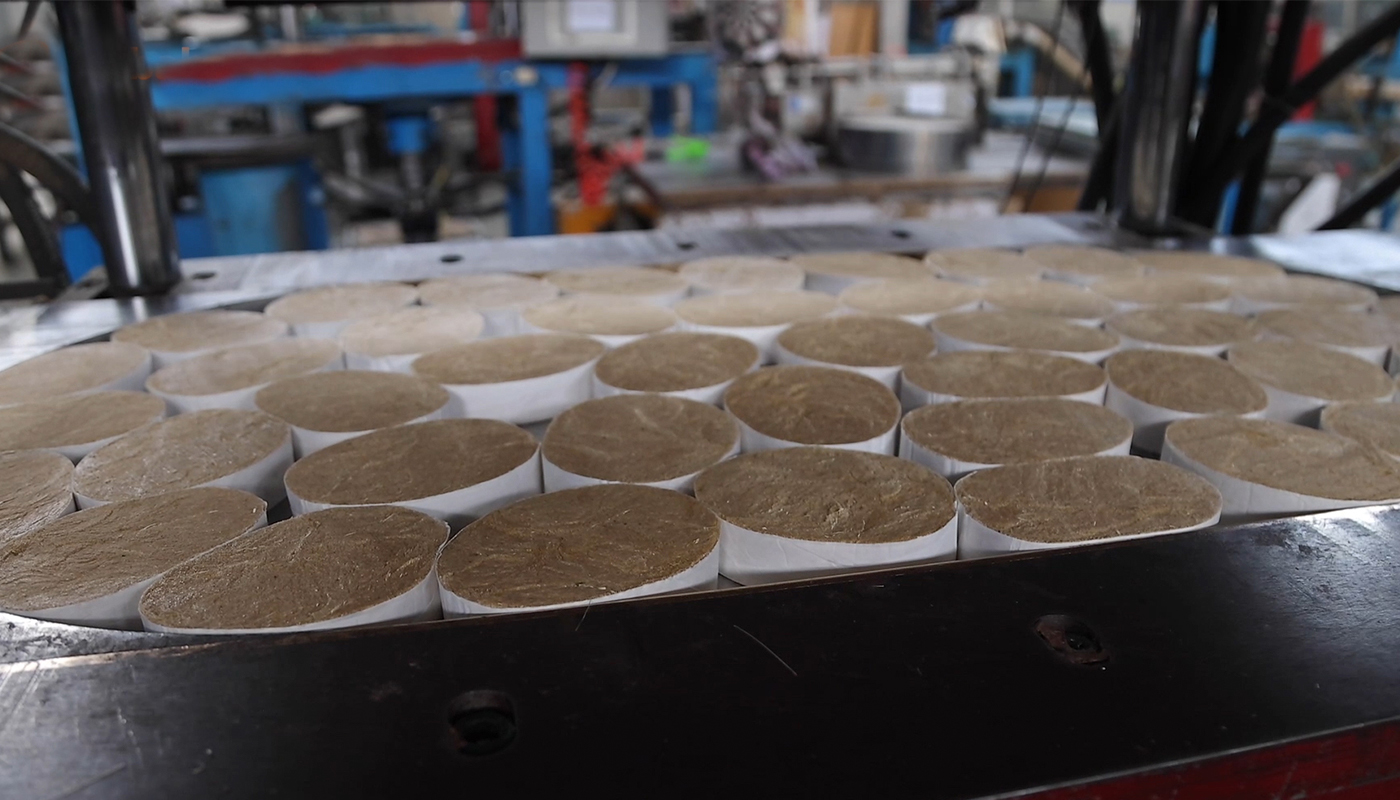

2. Sisal Compression and Board Formation

Conditioned fibers are compressed under extreme pressure to form dense blocks.

Critical factors include:

-

Fiber density consistency

-

Compression uniformity

-

Structural stability

Blocks are then cut into precise segments that form the dartboard surface.

3. Board Surface Assembly

Segments are bonded together to create the full dartboard face.

At this stage, factories ensure:

-

Uniform hardness across scoring zones

-

Accurate bullseye positioning

-

Flat and stable board surfaces

4. Wiring System Installation

Metal wiring is installed to divide scoring areas.

Key technical requirements:

-

Exact wire thickness

-

Accurate spacing between segments

-

Secure embedding to reduce bounce-outs

Number rings are installed according to international layout standards.

5. Frame and Backboard Construction

The dartboard backing is attached to provide structural support and wall-mount stability.

Backing materials are tested for:

-

Impact absorption

-

Long-term deformation resistance

-

Mounting strength

6. Dartboard Quality Testing

Each dartboard undergoes multiple inspections:

-

Penetration depth testing

-

Fiber recovery (self-healing) tests

-

Surface flatness checks

-

Visual alignment inspection

Only boards that meet durability and performance criteria are approved.

Part 3: Customization, Packaging, and Logistics

For OEM and private-label clients, factories provide:

-

Custom color schemes and number styles

-

Logo printing on boards or packaging

-

Retail-ready and e-commerce packaging solutions

Packaging is designed to protect products during long-distance shipping and comply with international transport standards.

Conclusion

The manufacturing of darts and dartboards is a highly specialized process that combines material science, precision machining, and strict quality control. From CNC-machined dart barrels to compressed sisal dartboard surfaces, every production step directly impacts performance and longevity.

By working with an experienced dart manufacturing factory, brands and distributors gain consistent quality, customization flexibility, and reliable global supply — all essential for long-term success in the darts market.

FAQ

1. Why is tungsten preferred for dart barrels?

Tungsten allows slimmer barrels at the same weight, improving grip control and accuracy for players.

2. How do factories ensure dartboard durability?

Through high-density sisal compression, controlled moisture conditioning, and penetration testing.

3. Are dart and dartboard processes handled in the same factory?

Professional manufacturers often have separate production lines to maintain specialization and quality.

4. Can factories customize both darts and dartboards?

Yes. OEM services typically include logo branding, color customization, and packaging design.

5. How long does production take for custom orders?

Depending on complexity and volume, production usually takes 3–6 weeks.

How Darts Are Made: A Detailed Look at Modern Dart Production Lines

Inside a Professional Dart Factory: Step-by-Step Production Explained

From Raw Materials to Finished Product: The Complete Dart Manufacturing Process

A Complete Buyer’s Guide to Choosing the Right Custom Dart Factory in China

Why Custom Darts Are Trending in the Global Home Entertainment Market

Dartboard surrounds

Does the guard material support personalized color customization?

Yes, customers can choose a variety of colors, and can also add brand logos or patterns.

Dart usage scenarios

Are dart guards suitable for training schools?

Yes, it can protect the wall and reduce the risk of damage caused by dart errors.

Dart boards

Does the dart board support QR code customization?

Yes, QR codes can be printed on the board or packaging for brand promotion or event traffic.

Services provided

Do you provide a complete report after order processing?

Yes, we provide customers with detailed reports after order processing, including production progress, quality inspection results, shipping information, etc., to ensure that customers understand every link.

Payment method

Does it support local currency payment?

Yes, the specific currency payment method can be determined according to the country where the customer is located.

Custom wholesale 18g 90% tungsten safety dart

Made of high-density tungsten steel, this dart provides excellent stability and precise control. Its compact design combined with a high-quality grip ensures comfort and accuracy when throwing, making it an ideal choice for professional dart players.

Custom High Quality 18 Inch Brazilian Sisal Dart Board

This Brazilian Sisal Dart Board is made of high-quality Brazilian Sisal fiber, which has excellent self-healing function. The darts can recover quickly after being pulled out, extending the service life. Its sturdy and durable structure and professional design are suitable for all kinds of dart enthusiasts, whether it is family entertainment or competitive competition, it can provide an excellent gaming experience.

Custom Bristle Steel Tip Dartboard Set Spider Wire Compressed Sisal Board with Rotating Number Ring

This Round line sisal dart board is made of high-quality sisal fiber, with self-healing function to extend its service life. The classic round wire isolation design is durable and stable, suitable for family entertainment and dart beginners, making every throw full of fun. Suitable for home, bar, game room and other places, it is your ideal choice for relaxation and socializing

Wholesale custom pattern PU dartboard surround

PU dartboard surround is a dart board accessory made of high-strength polyurethane material, providing all-round protection to prevent darts from damaging walls or furniture and extend the service life of the dart board.

Discover SKIPJACK’s Custom Dart Solutions

SKIPJACK offers darts custom-made solutions designed for excellence. Improve your game with our precision-crafted, customized darts.

Whatsapp: +8615919340906

SKIPJACK DARTS

SKIPJACK DARTS

SKIPJACK DARTS