Do Pros Use Moulded Flights? | Insights by SKIPJACK

Preface

In the world of precision components and engineering, the choice of materials and design features can have a monumental impact on performance, efficiency, and reliability. One component that is gaining increasing attention for its advantages is the moulded flight. We explore whether seasoned professionals in the industry are turning towards molded flights, elucidating the benefits and reviewing their suitability for extensive professional applications.

What are Moulded Flights?

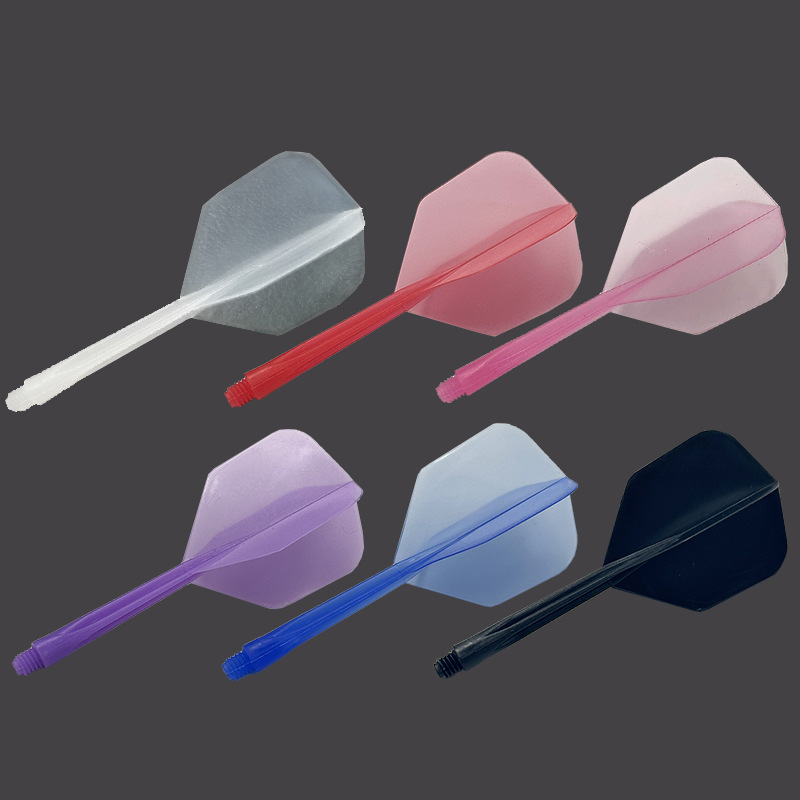

Moulded flights refer to fixed structures that are precisely manufactured using a moulding process. This allows for a high degree of consistency and precision, offering several beneficial characteristics. Professionals often gravitate toward innovations that enhance efficiency and reliability, which is where molded flights shine.

Are Moulded Flights Any Good?

Moulded flights can be a good option for many players, as they are durable, consistent, and require less maintenance compared to traditional folded flights. Made from a single piece of material, they are less likely to separate or break, offering better flight stability. However, some players may prefer the feel and customization of traditional flights. It ultimately depends on personal preference and playing style.

Do Darts Players Use Moulded Flights?

Yes, some darts players use molded flights. Moulded flights, made from durable materials like plastic, offer consistency in shape and flight path, reducing the need for frequent replacements. They are popular among players who prefer stability and longevity, though some players still opt for traditional folded flights for their feel and customization options. The choice depends on personal preference and playing style.

Why Professionals Consider Moulded Flights

Precision Engineering

Moulded flights benefit from the inherent precision of the moulding process. This enables manufacturers to achieve high accuracy in dimensions, resulting in a consistent shape. In engineering sectors where precision is non-negotiable, this feature alone can be invaluable.

Durability and Strength

The manufacturing process of moulded flights typically results in a product that combines the benefits of uniformity and enhanced structural integrity. Professionals are more likely to opt for components that promise longevity and strength, reducing maintenance costs and downtime in demanding applications.

Cost-Efficiency

The initial investment in molded flights can be higher, as it often involves custom mold development. However, for large-scale projects, the benefits in efficiency and reduced waste make them a cost-effective choice. When looking at long-term project execution, the initial costs can be easily offset by the operational savings.

Applications of Moulded Flights

Industries and Utilization

Industries such as chemical processing, food and beverage, and materials handling often demand a high level of consistency and hygiene—requirements that molded flights can meet effectively. They are used in screw conveyors and augers, where precise component fitment is critical for seamless operation.

Versatility

Moulded flights are engineered to tolerate a variety of materials and operational conditions. This versatility makes them suitable for professionals across different sectors, bolstering their appeal as a multipurpose solution.

Conclusion

In sum, the adoption of molded flights by professionals is a testament to their enhanced precision, durability, and cost-efficiency. In industries where quality and performance are paramount, molded flights deliver unmatched value. With SKIPJACK, understand the advantages and the broad scope of applications that these components offer and why they might be the right choice for your next project.

Feel free to navigate our website or consult with our expert team at SKIPJACK to explore molded flight solutions tailored to your needs.

From Raw Materials to Finished Product: The Complete Dart Manufacturing Process

A Complete Buyer’s Guide to Choosing the Right Custom Dart Factory in China

Why Custom Darts Are Trending in the Global Home Entertainment Market

Dropshipping Custom Darts: Opportunities and Challenges for Online Sellers

How to Source Reliable Custom Dart Manufacturers for Global E-Commerce

Services provided

Can customers visit the factory?

Customers are welcome to visit the factory in person or take an online factory tour through video conferencing.

Customized service

Can it be produced according to customer design drawings?

Yes, after the customer provides the drawings, we will conduct a feasibility analysis and feedback.

Darts

How to choose the right dart weight for yourself?

The choice of weight should be based on personal throwing habits. Beginners are recommended to use 14-18 grams, and advanced players can choose heavier darts (20-24 grams).

Payment method

Does it support local currency payment?

Yes, the specific currency payment method can be determined according to the country where the customer is located.

Dartboard surrounds

Will the thickness of the guard affect the use?

The thickness of the guard is optimized to protect the wall without affecting the normal use of the dart.

Custom High Quality 18 Inch Brazilian Sisal Dart Board

This Brazilian Sisal Dart Board is made of high-quality Brazilian Sisal fiber, which has excellent self-healing function. The darts can recover quickly after being pulled out, extending the service life. Its sturdy and durable structure and professional design are suitable for all kinds of dart enthusiasts, whether it is family entertainment or competitive competition, it can provide an excellent gaming experience.

Custom Bristle Steel Tip Dartboard Set Spider Wire Compressed Sisal Board with Rotating Number Ring

This Round line sisal dart board is made of high-quality sisal fiber, with self-healing function to extend its service life. The classic round wire isolation design is durable and stable, suitable for family entertainment and dart beginners, making every throw full of fun. Suitable for home, bar, game room and other places, it is your ideal choice for relaxation and socializing

Wholesale custom pattern PU dartboard surround

PU dartboard surround is a dart board accessory made of high-strength polyurethane material, providing all-round protection to prevent darts from damaging walls or furniture and extend the service life of the dart board.

Professional 301 Steel Tip Darts Set

Discover SKIPJACK’s Custom Dart Solutions

SKIPJACK offers darts custom-made solutions designed for excellence. Improve your game with our precision-crafted, customized darts.

Whatsapp: +8615919340906

SKIPJACK DARTS

SKIPJACK DARTS

SKIPJACK DARTS