How Do You Make Your Own Dart Products? A Guide to Custom Darts

Darts are a staple in both casual and professional game rooms, but have you ever wondered how to make your own dart products? Whether you're a new business looking to launch a dart brand or an enthusiast wanting a personalized dart set, the process of creating custom darts is more accessible than you might think. Here's everything you need to know about manufacturing your own dart products, including options for customization and working with specialized manufacturers.

Understanding the Basics of Dart Manufacturing

Before diving into the creation of your custom darts, it's essential to understand the basic components involved:

-

Dart Tip: The metal tip that strikes the dartboard. It's typically made of steel or soft plastic, depending on whether you're designing for steel-tip or soft-tip darts.

-

Barrel: This is the main body of the dart, where players grip it. Barrels are usually made from brass, tungsten, or other materials that offer durability and weight.

-

Shaft: The shaft connects the barrel to the flight and can be made from various materials, including plastic or aluminum. The design of the shaft can influence the aerodynamics of the dart.

-

Flight: The flight controls the dart's trajectory and stability in flight. It can be designed in various shapes and materials to improve precision.

Choosing Your Customization Options

When creating custom darts, you can adjust several aspects of the product to match your preferences or brand identity. Here are the most common customization options:

-

Barrel Weight and Shape: The weight of the barrel impacts the dart’s balance and speed. You can choose from a wide range of weights (typically from 18g to 30g) to suit different players’ styles. Additionally, barrels come in different shapes—straight, torpedo, or even unique designs tailored to the player's needs.

-

Grip Design: A crucial aspect for players, the grip can be tailored to enhance comfort and control. You can create various textures, from smooth to deeply grooved, depending on what offers the best feel for your target audience.

-

Shaft Length and Material: Shaft length affects the aerodynamics and stability of the dart. Shorter shafts are generally more stable, while longer ones may allow for a more dynamic throw. Material choice—such as aluminum or plastic—will also impact the dart’s performance.

-

Flight Style and Branding: The flight's shape influences the dart's accuracy. You can customize the shape (standard, slim, kite, etc.) and design (logos, colors, or themes) to match the branding of your product.

Working with a Manufacturer

Manufacturing your own darts is a lot more straightforward when you partner with an experienced manufacturer that specializes in customization. One such company is SKIPJACK DARTS, a comprehensive manufacturer that has been in the business for over a decade, offering end-to-end solutions for custom darts. They provide both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, allowing customers to either develop entirely new designs or tweak existing ones to suit their needs.

SKIPJACK offers a variety of customization options, including:

-

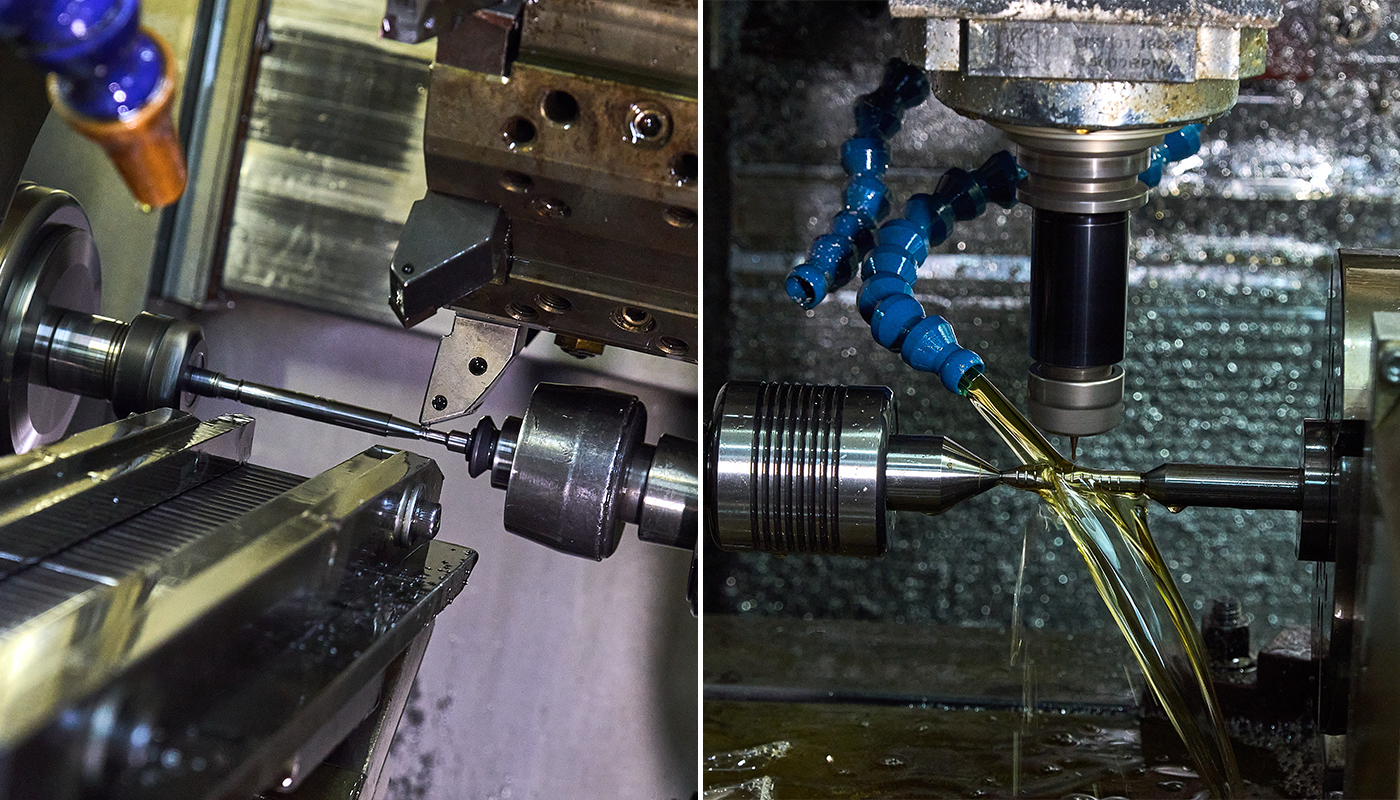

CNC Precision Crafting: For custom textures and grips, SKIPJACK uses advanced CNC precision technology to create unique patterns and textures that enhance the player's grip and improve performance.

-

Custom Packaging: Not just the darts themselves—SKIPJACK also offers tailored packaging, which can be a great way to elevate your product's presentation and branding.

-

Environmental Considerations: Their products are made using materials that comply with global standards like RoHS and REACH, ensuring safety and sustainability in production.

By working with a specialized manufacturer like SKIPJACK, you can ensure that every aspect of your custom darts meets the desired specifications.

The Manufacturing Process

The process of making your own dart products typically involves several key steps:

Step 1: Design Conceptualization

Before anything gets made, you’ll need to decide on the design for your darts. Work with designers to choose the material, shape, size, and weight of the darts, as well as any personalization options like custom logos, color schemes, or text.

Step 2: Prototyping

Once you have your design, it’s time to create a prototype. Some manufacturers, including SKIPJACK, offer rapid prototyping services that allow you to see and feel the dart before committing to mass production. This is a crucial step to ensure everything from the weight distribution to the grip feels just right.

Step 3: Production

After finalizing the prototype, the manufacturer will begin the production process. For customized darts, this involves creating the barrels, tips, shafts, and flights, and assembling them into complete darts. The quality of each part will be meticulously checked to ensure the final product meets industry standards for durability, balance, and flight accuracy.

Step 4: Testing

The manufacturer will conduct quality control tests on the darts, such as balance checks, durability tests, and flight accuracy assessments. Some companies like SKIPJACK even offer performance testing facilities to ensure that every dart performs as expected, whether in professional tournaments or recreational play.

Step 5: Packaging and Shipping

Once the darts are manufactured and tested, they’re packaged for shipment. Custom packaging options allow you to make your brand stand out, whether it's through sleek cases, branded pouches, or eco-friendly packaging.

Considerations for Your Dart Product Line

-

Market Research: Before launching, do some research into your target market. Are you catering to professional dart players, casual enthusiasts, or both? The needs of these groups can vary greatly, so understanding your audience is key.

-

Branding and Marketing: Custom darts are a fantastic way to enhance brand recognition, so don’t forget to focus on the branding and marketing aspect of your product. Use your custom flights, packaging, and logo to create a cohesive experience for your customers.

-

Compliance: Make sure that your custom darts meet safety and quality standards. For example, SKIPJACK ensures that its products comply with international standards like RoHS and REACH, which is crucial if you plan to sell globally.

Conclusion

Making your own dart products can be a rewarding venture that allows you to create something unique for both players and fans. By working with a manufacturer like SKIPJACK, you can leverage their expertise in customization, design, and production to bring your vision to life. Whether you're launching a brand or creating a personalized set for yourself, understanding the components of dart design, selecting the right customization options, and working with the right team are all essential steps to success.

Dropshipping Custom Darts: Opportunities and Challenges for Online Sellers

How to Source Reliable Custom Dart Manufacturers for Global E-Commerce

Best-Selling Custom Dart Ideas for Amazon and Shopify Stores in 2025

Boost Your Promotional Campaigns with Branded Dartboards

Custom Darts as Premium Corporate Gifts: A Unique Way to Impress Clients

Payment method

Do I need to pay for the design of the custom product?

Usually a small design fee is charged, but it can be refunded after the order reaches a certain quantity.

Dart boards

Which entertainment venues are dart products suitable for?

Suitable for bars, clubs, game halls and family entertainment venues.

Dart Shafts

What is the color coating process of the dart shaft?

We use multiple processes such as electrophoretic spraying, anodizing, chrome plating, etc. to ensure uniform color and high wear resistance.

Services provided

What do you do if the product is damaged during transportation?

We will strictly pack before transportation and provide insurance protection for customers. If damage occurs, we will provide return and exchange services according to the situation.

FAQ

What quality assurance measures do you have?

We have a comprehensive quality assurance process, including material selection, in-process testing, and final inspection to ensure that each dart product meets our high standards. We are committed to providing reliable and durable dart products.

Custom PET darts flights shapes

Dart flights stabilize flight paths and improve throwing accuracy. Made from durable, lightweight materials, they come in various shapes and designs to suit players' needs, combining functionality with style.

Custom Dart Flights Manufacturer | OEM Logo Printed Flights in Bulk

Hot sale 23G 90% Tungsten Steel Tip Darts PVD Blue Engraving

High-density tungsten steel gives this dart excellent stability and accuracy, ensuring that every throw is more stable and accurate. Its compact design and non-slip grip make it suitable for all types of dart enthusiasts, especially for precise control and long-term training.

OEM Steel Tip Darts Manufacturer Custom Logo & Packaging for Brands

Discover SKIPJACK’s Custom Dart Solutions

SKIPJACK offers darts custom-made solutions designed for excellence. Improve your game with our precision-crafted, customized darts.

Whatsapp: +8615919340906

SKIPJACK DARTS

SKIPJACK DARTS

SKIPJACK DARTS