How to Sharpen Darts: A Guide from the Manufacturer's Perspective

As a factory specializing in the production of high-quality darts, ensuring optimal performance for our products is paramount. One critical aspect of dart maintenance is keeping the dart tips sharp, which enhances precision, minimizes bounce-outs, and prolongs the lifespan of the dartboard. Here, we’ll delve into the process of sharpening darts, highlighting the manufacturing perspective to ensure you get the best results.

1. Why Is Sharpening Darts Important?

Sharpening is not just about the dart’s appearance—it’s about maintaining performance. Over time, dart tips can become dull due to frequent impact with the dartboard. A properly sharpened dart:

- Improves accuracy by reducing deflection.

- Protects the dartboard surface by ensuring clean penetration.

- Minimizes bounce-outs by allowing the dart to grip the board effectively.

As manufacturers, we design our dart tips using high-grade materials, such as carbon steel, to ensure they retain sharpness for as long as possible. However, even the best materials need maintenance.

2. Tools for Sharpening Darts

Factories often utilize industrial-grade tools to achieve precise sharpening during production. For individual players or retailers, the following tools are recommended:

- Dart Sharpening Stones: Compact and portable, perfect for players.

- Rotary Sharpeners: Ideal for consistent results.

- Professional Grinding Machines: Used in factories for mass sharpening with precision.

Our factory employs advanced CNC machines for precise tip shaping, ensuring each dart meets professional standards.

3. The Sharpening Process

Whether you’re a player or a retailer managing inventory, the method remains consistent.

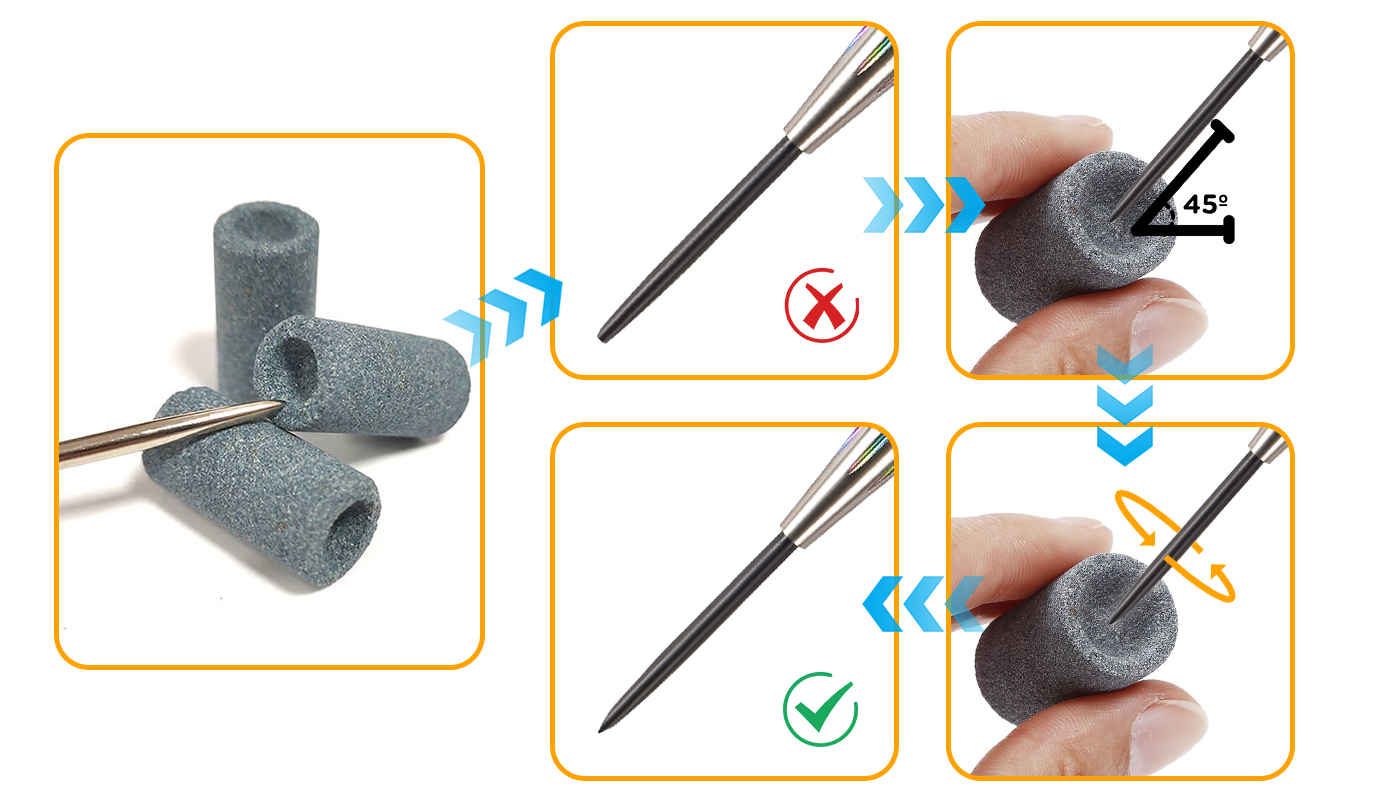

Step-by-Step Guide:

- Assess the Tip Condition: Check for dullness or deformation.

- Choose the Right Tool: At the factory, we use high-speed grinders, but for personal use, a sharpening stone works well.

- Angle the Dart Tip: Keep a consistent 45-degree angle to avoid over-sharpening, which can weaken the tip.

- Rotate and Sharpen: Gently rotate the dart tip against the sharpening tool, ensuring uniform sharpness.

- Test the Tip: Lightly press it against your finger (cautiously). It should feel sharp but not needle-like, as overly pointed darts can damage boards.

4. Tips from a Factory Perspective

- Material Matters: As manufacturers, we ensure the dart tips are made from durable metals, making sharpening less frequent.

- Avoid Over-Sharpening: Excessively sharp darts can “dig” into the dartboard, causing unnecessary wear.

- Maintenance is Key: Even with factory-sharpened darts, regular upkeep by the end user ensures long-lasting performance.

-

5. Common Mistakes to Avoid

- Using Improper Tools: Sandpaper or coarse files can damage the tip’s integrity.

- Incorrect Angle: Too steep or flat an angle compromises the performance of the dart.

- Ignoring Maintenance: Regular checks save time and prolong dartboard life.

Conclusion

Sharpening darts is an essential skill for any player, retailer, or factory involved in the world of darts. At our factory, we combine advanced production techniques with rigorous quality checks to ensure every dart performs to its maximum potential. With proper sharpening and maintenance, players can enjoy the precision and durability of their darts for years to come.

If you’re interested in learning more about our dart manufacturing processes or need professional guidance on dart maintenance, feel free to reach out to us!

OEM & ODM Darts: How Manufacturers Turn Your Brand Ideas into Reality

The Technology Behind Precision Custom Darts: From CNC Machining to Laser Engraving

Why Working Directly with a Dart Factory Guarantees Better Customization and Quality

Inside the Process: How Custom Darts Are Manufactured from Start to Finish

How Professional Dart Manufacturers Are Powering the Global Dart Industry

Dart bags

What protective features does the dart bag have?

The dart bag has a foam compartment to prevent the darts from being damaged during transportation.

Customized service

Can dart cabinets be used as home decorations?

Yes, high-end dart cabinets have both practical and decorative functions.

Can it be produced according to customer design drawings?

Yes, after the customer provides the drawings, we will conduct a feasibility analysis and feedback.

Darts

What if the dart product is damaged during transportation?

Replacement or compensation services are provided, and insurance transportation services are recommended.

Dart usage scenarios

Are darts suitable for corporate team-building activities?

Very suitable, dart games can enhance teamwork and employee cohesion.

Wholesale custom pattern PU dartboard surround

PU dartboard surround is a dart board accessory made of high-strength polyurethane material, providing all-round protection to prevent darts from damaging walls or furniture and extend the service life of the dart board.

Professional 301 Steel Tip Darts Set

Wholesale custom Square EVA dartboard surround

The EVA target guard is made of high-density EVA material, which is light and durable, with excellent protection effect, can effectively absorb the impact of darts and protect the wall from damage. It is easy to install and suitable for all kinds of dart boards. It is an ideal choice for home entertainment, game rooms and other places.

Custom Bristle Steel Tip Dartboard Set Spider Wire Compressed Sisal Board with Rotating Number Ring

This Round line sisal dart board is made of high-quality sisal fiber, with self-healing function to extend its service life. The classic round wire isolation design is durable and stable, suitable for family entertainment and dart beginners, making every throw full of fun. Suitable for home, bar, game room and other places, it is your ideal choice for relaxation and socializing

Discover SKIPJACK’s Custom Dart Solutions

SKIPJACK offers darts custom-made solutions designed for excellence. Improve your game with our precision-crafted, customized darts.

Whatsapp: +8615919340906

SKIPJACK DARTS

SKIPJACK DARTS

SKIPJACK DARTS