Steel Tip Darts Manufacturing: Factory Guide to Quality Production

Steel tip darts remain the top choice for serious players and competitive leagues around the world. But behind every high-performance dart lies a complex and meticulous manufacturing process. As a dedicated factory with over a decade of experience in dart production, we’re here to give you a detailed guide on how steel tip darts are made, what materials are used, and how quality is controlled every step of the way.

- 1. What Are Steel Tip Darts?

- 2. Raw Materials Used in Manufacturing

- 3. Dart Manufacturing Process

- Step 1: Barrel Machining

- Step 2: Surface Treatment

- Step 3: Tip Insertion

- Step 4: Assembly

- Step 5: Weight & Balance Testing

- 4. Quality Control Standards

- 5. Customization & OEM/ODM Services

- Conclusion

- FAQs

1. What Are Steel Tip Darts?

Steel tip darts are designed for use with bristle dartboards (usually made from sisal fibers). Unlike soft tip darts, which are used on electronic boards, steel tip darts feature a sharp metal point that penetrates deeply into the board for consistent scoring. These darts are favored for their precision, weight, and long-term durability.

2. Raw Materials Used in Manufacturing

In our factory, the production of steel tip darts begins with the careful selection of raw materials. The quality of these materials directly impacts dart performance and lifespan.

-

Barrel Materials: We use brass, stainless steel, and tungsten. Tungsten is the most premium option due to its high density, allowing for slimmer barrels without sacrificing weight.

-

Tips: Precision-engineered from hardened steel for durability and minimal bounce-outs.

-

Shafts: Made from aluminum, nylon, or carbon composite depending on the desired flexibility and strength.

-

Flights: PET and laser materials offer great lift, while metal flights are more durable and aerodynamic.

3. Dart Manufacturing Process

Here’s a step-by-step overview of our steel tip dart production:

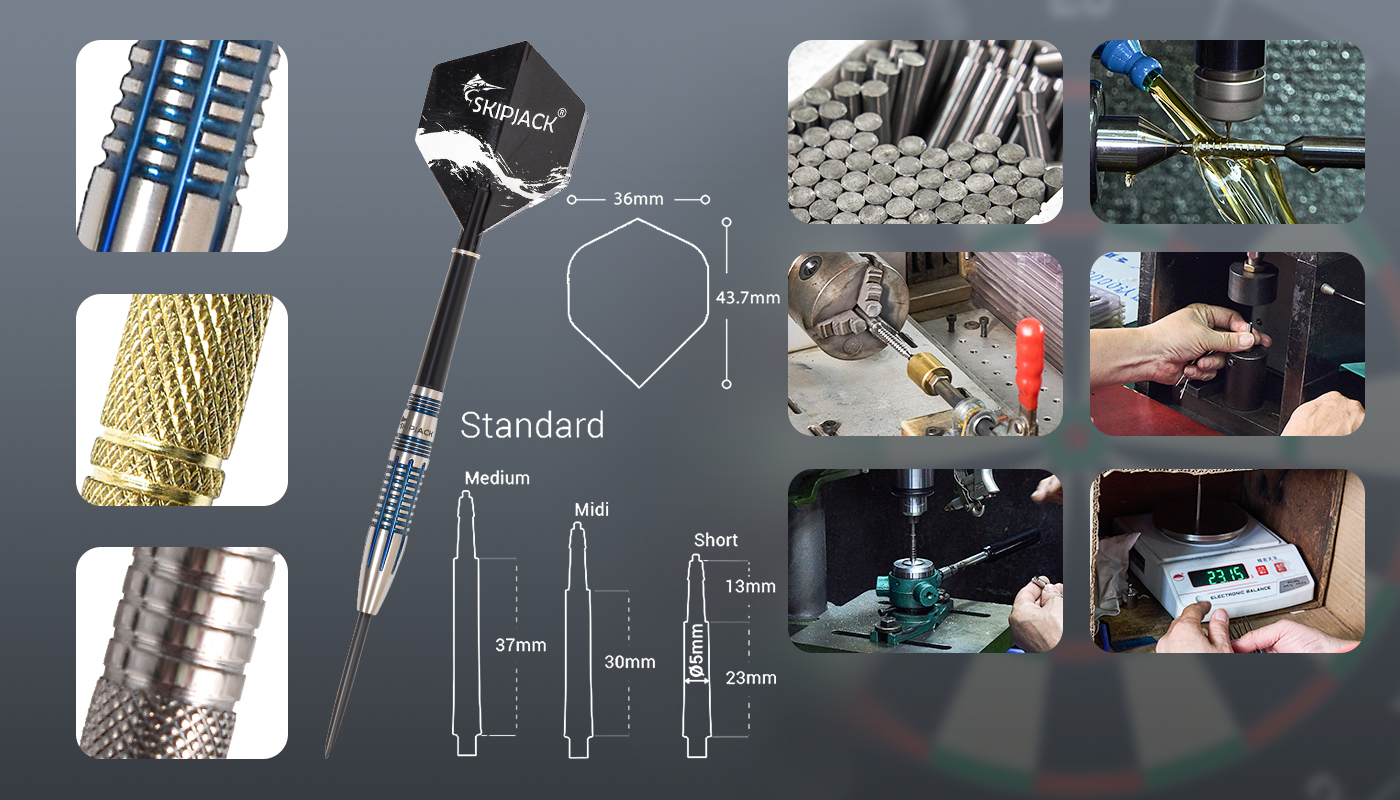

Step 1: Barrel Machining

Each barrel is CNC-machined with precision to meet specific weight, grip, and balance requirements. Tungsten alloys require careful machining due to their hardness.

Step 2: Surface Treatment

Barrels are polished, painted, or electroplated for aesthetics and grip enhancement. Popular finishes include sandblasted matte black, electroplated chrome, or titanium coating.

Step 3: Tip Insertion

Steel tips are press-fitted or glued into the barrels with industrial-strength adhesives. We also offer replaceable point options for high-level players.

Step 4: Assembly

Dart shafts and flights are manually assembled and checked for symmetry and balance.

Step 5: Weight & Balance Testing

Each dart set is tested to ensure uniform weight and perfect center balance. Our tolerance is within ±0.1g to maintain consistency.

4. Quality Control Standards

Strict quality control is what sets reliable dart manufacturers apart. Our factory implements:

-

Raw material inspection

-

In-process QC at every machining and assembly stage

-

Final inspection for weight, straightness, and sharpness

-

Packaging quality assurance

We’re also ISO 9001 certified, ensuring consistent standards across all batches.

5. Customization & OEM/ODM Services

For brands and distributors, we offer a full range of customization options:

-

Custom barrel design (weight, grip, engraving)

-

Custom shafts and flights (color, material, logo printing)

-

Packaging solutions: gift boxes, blister packs, retail-ready kits

-

OEM branding and white-label production

Our in-house design and engineering team can take your idea from concept to shelf-ready product.

Conclusion

Manufacturing high-quality steel tip darts requires more than just raw materials and machinery—it takes experience, precision, and a deep understanding of dart mechanics. As a professional dart factory, we are committed to producing reliable, competition-ready darts that players around the world can trust. Whether you are a brand looking to expand your product line or a distributor in search of a dependable supplier, we are ready to support your success in the darts market.

FAQs

Q1: What’s the best material for steel tip dart barrels?

A: Tungsten is considered the best due to its high density, allowing slimmer, more accurate barrels.

Q2: Can I customize the weight and design of the darts?

A: Yes. We offer full OEM/ODM services, including custom weights, grips, colors, and logos.

Q3: How long does it take to manufacture a bulk order?

A: Typically 25–35 days depending on order size and customization level.

Q4: What kind of packaging do you offer?

A: We provide gift boxes, blister packs, PVC tubes, and retail packaging, all customizable with your branding.

Q5: Do you manufacture both steel tip and soft tip darts?

A: Yes, our factory produces both types, and we can also provide hybrid dart sets upon request.

How Darts Improve Focus, Coordination, and Stress Relief

The Future of Dart Games: Technology, Innovation, and Global Market

Darts as a Trendy Gift Idea: From Birthdays to Corporate Events

Choosing the Right Dartboard: A Complete Buyer’s Guide

How Dart Products Help Businesses Boost Customer Engagement and Brand Exposure

FAQ

What materials are your dartboards made from?

Our traditional dartboards are made from high-quality sisal fibers, known for their durability and self-healing properties, while our electronic dartboards are made from tough ABS and other durable materials.

Darts

What are the main materials of darts and dart boards?

Darts are generally made of copper, nickel silver or tungsten, and dart boards are usually made of high-quality sisal fiber to ensure durability and resilience.

Dart usage scenarios

Are dart products suitable for commercial promotional gifts?

Yes, dart sets have high practicality and customization value, and are ideal promotional gifts.

Services provided

What logistics options do you provide?

We provide a variety of logistics options, including sea, air, express and rail transportation. Customers can choose the most suitable method according to timeliness and cost requirements.

Dart bags

Does the dart bag support custom logos?

Yes, the brand can customize the exclusive logo according to needs.

Amazon's best-selling steel tip darts

Dominate the dartboard with SKIPJACK's Amazon best-selling steel tip darts. Experience superior quality and flight. These steel tip darts are a favorite on Amazon – order yours today!

Family Fun Steel Tip Darts game

SKIPJACK High quality steel tip darts for standard dartboard

Elevate your game with SKIPJACK high-quality steel tip darts. Perfect for standard dartboards, these SKIPJACK darts offer superior performance and precision. Experience the difference.

Factory Direct Steel Tip Darts OEM/ODM

Discover SKIPJACK’s Custom Dart Solutions

SKIPJACK offers darts custom-made solutions designed for excellence. Improve your game with our precision-crafted, customized darts.

Whatsapp: +8615919340906

SKIPJACK DARTS

SKIPJACK DARTS

SKIPJACK DARTS