How to Make the Perfect Dart: Insights from Factory Production

Creating the perfect dart requires a seamless combination of precision engineering, advanced materials, and meticulous craftsmanship. In this article, we’ll explore the step-by-step process of producing high-quality darts from a factory perspective, highlighting key considerations in design, manufacturing, and quality control.

1. Design: The Blueprint of Precision

The process begins with designing the dart. Factors such as weight, shape, material, and balance are crucial for optimal performance.

- Material Selection: Tungsten is a popular choice for its density and durability, allowing for slim yet heavy darts.

- Aerodynamics: Designers use software simulations to analyze flight paths, ensuring stability during throws.

- Customization: Factories often offer OEM/ODM services, allowing clients to specify unique branding or features.

2. Material Preparation: Sourcing Quality Components

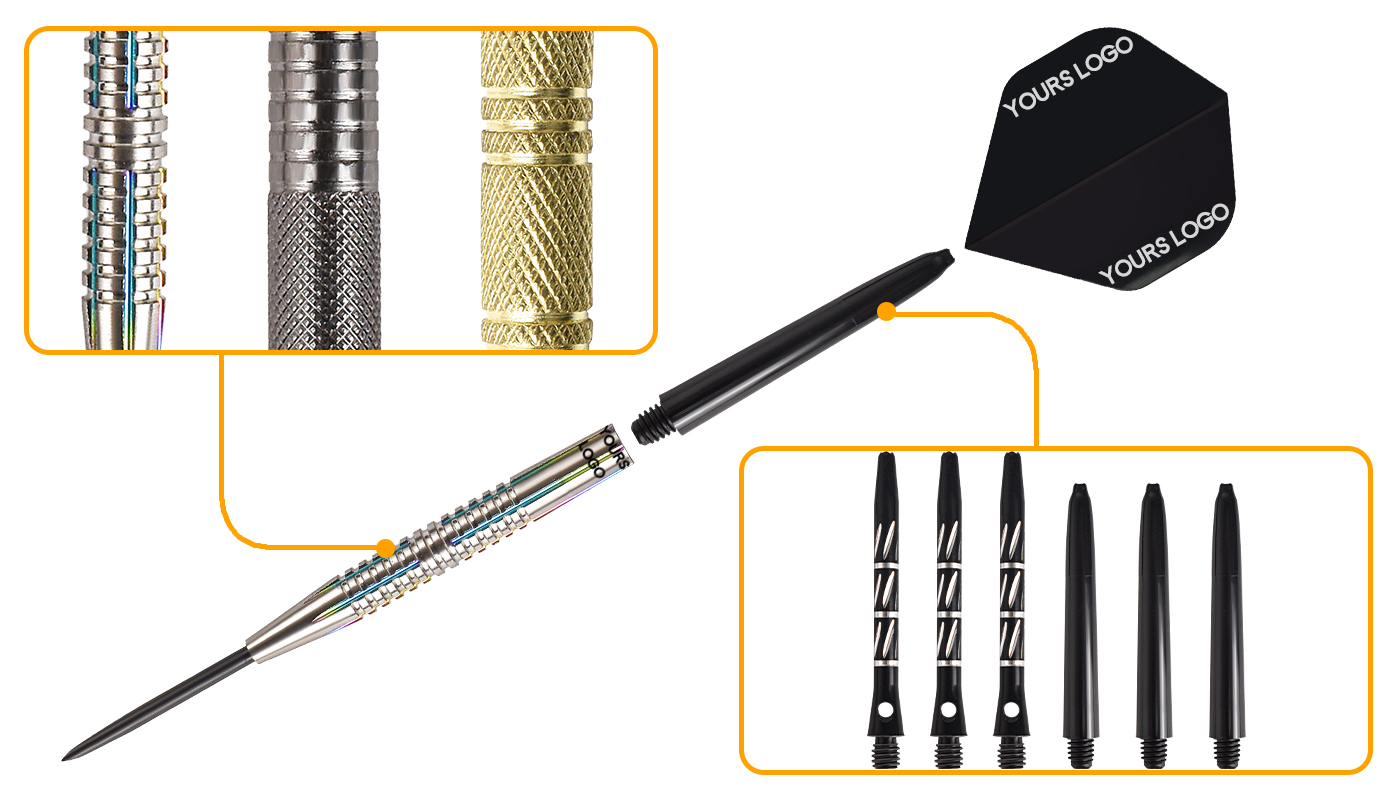

Factories source premium materials to ensure consistency and durability. Key components include:

- Barrels: Precision-machined from tungsten or brass.

- Shafts: Commonly made of aluminum, carbon fiber, or plastic for different levels of flexibility and weight.

- Flights: High-quality polymer sheets are cut and printed to provide stability and branding options.

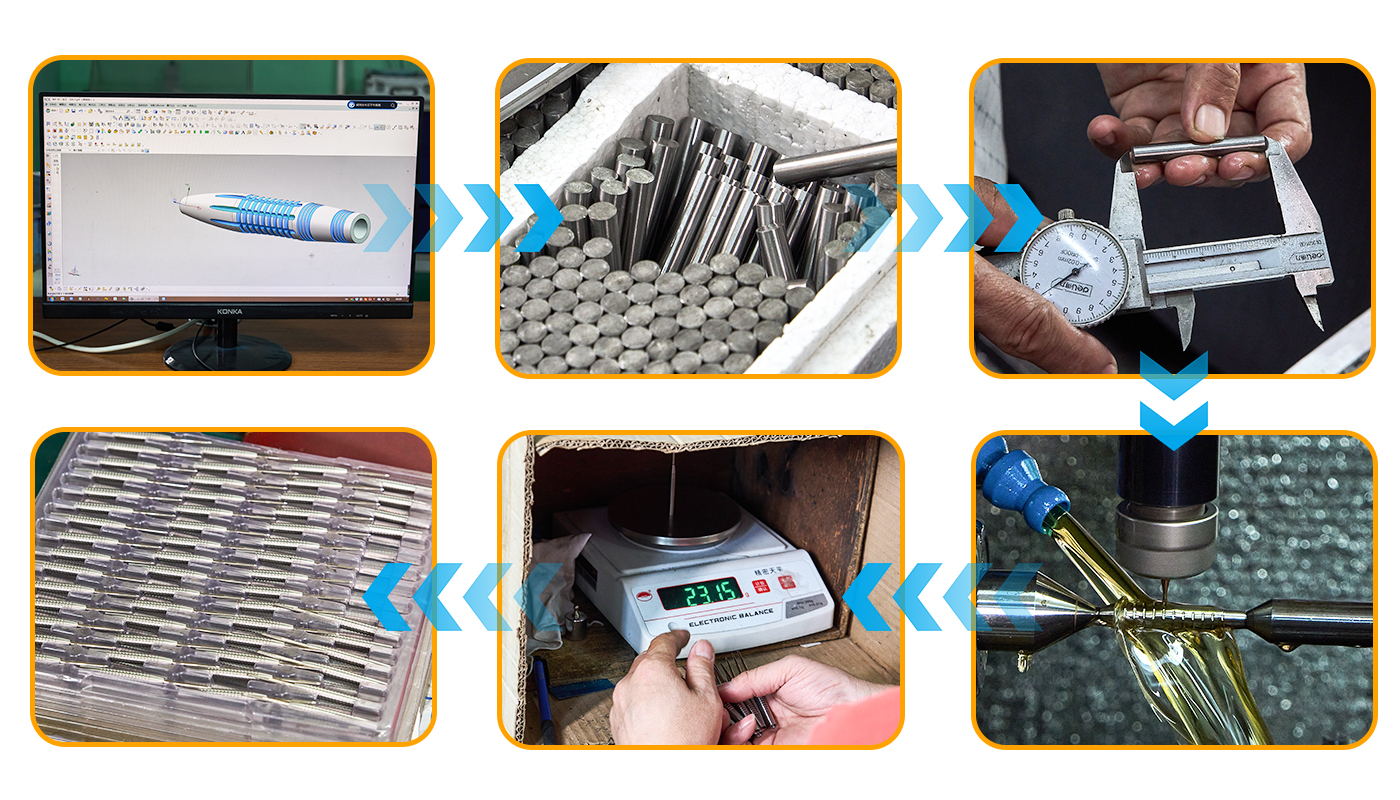

3. Manufacturing Process

Barrel Machining

The barrel is the heart of a dart. Factories use CNC (Computer Numerical Control) machines to ensure precise dimensions and intricate grip patterns.

- Weight Calibration: Every barrel is weighed and balanced to match specifications.

- Surface Finishing: Techniques like sandblasting, anodizing, or electroplating are used to enhance durability and appearance.

Assembly

Once individual components are ready, the dart is assembled:

- The shaft is screwed into the barrel.

- Flights are attached to the shaft.

- Tips (steel or soft) are added, depending on the dart type.

Printing and Branding

For custom orders, factories use UV printing or laser engraving to add logos, colors, and personalized designs.

4. Quality Control: Ensuring Perfection

Every dart undergoes rigorous quality checks, including:

- Weight Consistency: Ensuring all darts in a set are identical.

- Throw Tests: Testing aerodynamics and stability.

- Durability Tests: Assessing resistance to impact and wear.

5. Packaging: The Finishing Touch

Custom packaging is designed to protect the darts and appeal to target markets. Options include luxury gift boxes or eco-friendly solutions.

Conclusion

Producing the perfect dart is a meticulous process that balances craftsmanship, technology, and attention to detail. From material selection to precision machining and thorough quality control, every step ensures that players receive a product that enhances their game.

For factories, maintaining high standards in dart production not only guarantees customer satisfaction but also establishes a reputation for excellence in the global market.

Dropshipping Custom Darts: Opportunities and Challenges for Online Sellers

How to Source Reliable Custom Dart Manufacturers for Global E-Commerce

Best-Selling Custom Dart Ideas for Amazon and Shopify Stores in 2025

Boost Your Promotional Campaigns with Branded Dartboards

Custom Darts as Premium Corporate Gifts: A Unique Way to Impress Clients

Dart boards

Can the dart board be customized with multiple colors?

Yes, we support up to 6 colors of logo printing to meet brand needs.

What is the processing accuracy of the dart rod?

We use CNC precision machining, and the tolerance is controlled within ±0.01mm to ensure consistency.

Customized service

Is there a fast proofing service for customized dart products?

Yes, we provide fast proofing services, which can be completed within 7 working days at the fastest.

Dartboard surrounds

Can the guard fit non-standard dart boards?

It can be customized to fit dart boards of different sizes.

Services provided

How to ensure the quality and consistency of customer customized products?

We have established a strict quality management system. From raw material procurement to production process, quality control is carried out at every step to ensure the consistency and high standards of customized products.

Custom High Quality 18 Inch Brazilian Sisal Dart Board

This Brazilian Sisal Dart Board is made of high-quality Brazilian Sisal fiber, which has excellent self-healing function. The darts can recover quickly after being pulled out, extending the service life. Its sturdy and durable structure and professional design are suitable for all kinds of dart enthusiasts, whether it is family entertainment or competitive competition, it can provide an excellent gaming experience.

Custom Bristle Steel Tip Dartboard Set Spider Wire Compressed Sisal Board with Rotating Number Ring

This Round line sisal dart board is made of high-quality sisal fiber, with self-healing function to extend its service life. The classic round wire isolation design is durable and stable, suitable for family entertainment and dart beginners, making every throw full of fun. Suitable for home, bar, game room and other places, it is your ideal choice for relaxation and socializing

Wholesale custom pattern PU dartboard surround

PU dartboard surround is a dart board accessory made of high-strength polyurethane material, providing all-round protection to prevent darts from damaging walls or furniture and extend the service life of the dart board.

Professional 301 Steel Tip Darts Set

Discover SKIPJACK’s Custom Dart Solutions

SKIPJACK offers darts custom-made solutions designed for excellence. Improve your game with our precision-crafted, customized darts.

Whatsapp: +8615919340906

SKIPJACK DARTS

SKIPJACK DARTS

SKIPJACK DARTS